The addition of simple RFID tags to hospitals’ widely used pneumatic tube system has dramatically improved performance without needing a system rebuild.

Although email and the web have greatly diminished the need for physical mail in many situations, it’s important to remember that there are many real-world scenarios where a tangible, physical object must be sent, and bits can’t substitute for those. That’s the case in hospitals where various patient samples (fluids, tissue) must go to different labs. At the same time, medications and preparations need to be sent from the in-house pharmacy to the patient or even the operating area.

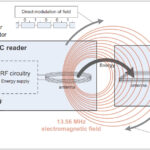

To solve this problem, pneumatic tube systems (PTS) are used, and these have existed for over 100 years. These PTSs accept and transport canisters (known as carriers) from an arbitrary sending station to a designated, selectable receiving station (Figure 1).

We all know that there are times when trying to keep a very old system and its underlying structure operating seems almost hopeless — think of your favorite PC, operating system, or application from a decade or more ago and the effort it takes to maintain it if it can be done at all. At the same time, there are some occasions when a modern technology upgrade can make a system that has become clogged under the weight of its success now perform like a bigger, better system at a modest cost and effort and with no new construction. Such is the case with the addition of RFID tags to pneumatic-tube routing systems.

A brief history

The earliest and simplest such systems used a physical hub-and-spoke network topology. The user put the load in the carrier, added an address label, placed the loaded carrier into the tube, closed the door, and pushed the “go” button. Compressed air would route the carrier to a central sorting location where someone looked at the destination label, placed the carrier in the appropriate outgoing tube, and sent it on its way.

While the activity in the bub could be hectic, from a user’s perspective, the system worked and was a critical part of an efficient hospital. (The alternative of using couriers, even within a building, was slow, inefficient, clogged hallways, and dependent on available personnel.) Eventually, automated routing hubs were developed, which read the carrier label and directed it to the destination tube.

Interestingly, before these systems were used for hospitals, they were used for postal mail in cities such as London and New York, with their crowded, traffic-jammed roadways and a high volume of mail — often time critical — between some neighborhoods. The decision to use these tubes versus surface transport was not made by the sender or recipient, and no “special-handling” surcharge or addressing was needed. Instead, the postal-system operators would decide which conveyance to use depending on the time of day, volume, and other factors. The references at the end have some fascinating historical information along with amazing photos of these underground systems.

The use of tubes for general mail became obsolete for many reasons (and this obsolescence occurred a long time ago, even before email slashed the volume of paper mail). However, using the pneumatic tube system in hospitals – where there is no viable alternative – has gone the opposite way, and its success has become its biggest problem.

[Note that there are also point-to-point pneumatic-tube systems; these are often used at bank or pharmacy drive-up windows to handle customers in car lanes which are not adjacent to the building itself. These systems use the carrier-and-tube principle but have none of the addressing or routing issues, as they are dedicated, fixed-route systems rather than flexible spoke-and-hub topologies with their arbitrary source and destination points.]

As medical and pharmaceutical technologies advanced, the number of patient tests performed has skyrocketed, along with patient samples or medications needing quick transport has also jumped. System traffic overloaded the hospital tubes, and adding more tubes is either too costly or impossible; it’s like adding more highway lanes in a crowded area (Figure 2).

Worse, if a carrier got stuck for whatever reason, it would block the lane of the tube system; if it got misrouted, the consequences could be worse, as the unintended recipient might not notice a carrier had mistakenly arrived and was at the wrong location.

The second and final part shows how a relatively simple wireless tag enables a major system upgrade and associated performance improvement and does so with the same “roadway.”

Related EE World content

Driverless Vehicles May Lead to Traffic Congestion in Cities

Analyst: 5G is all about the traffic

Adaptive Cruise Control Vehicles Create Phantom Traffic Jams in Road Test

New Smart System to Reduce Queues at Roundabouts

External References

Pneumatic Tubes for Hospitals

- Swisslog Healthcare, “TransLogic® Pneumatic Tube Systems”

- HCO News, “Pneumatic Tube Systems Help Deliver Better Patient Care”

- Wired, “Hospitals Still Use Pneumatic Tubes—and They Can Be Hacked”

- Penn Medicine News, “HUP’s P-Tube System: Keeping Services Up and Running”

- Air-Log International, “Pneumatic Tube Systems in hospitals”

- University of Iowa Medical Center, “Hidden health care: Guardians of the pneumatic tube system”

- Telecom Pneumatic Tube Systems, “Design issues in creating efficient Pneumatic Tube Transport networks”

- Stanford University, “Gone with the wind: Tubes are whisking samples across hospital”

- Wikipedia, “Pneumatic tube”

- Explain that Stuff, “Pneumatic tube transport”